services |

DESIGN

MRI Shielding Is Not Just A Simple 6-Sided,

One-Size-Fits-All Solution

When evaluating MRI shielding firms there are key areas of expertise you should look for.

Optimal MRI shielding design requires a clear understanding of existing or planned site conditions, user needs, and constructibility. It also requires experience that successfully addresses the physics of MRI equipment including radio-frequency interference, magnetic field containment and acoustic noise impact.

There is no replacement for the skills that only come with in-the-field experience: a track record of projects that maximize safety, functionality and the clinical environment.

CONSULTING

WE HAVE WHAT IT TAKES

NMR and MRI shielding requires a very specific set of knowledge and experience.

Our experience, combined with the resources of IMEDCO AG, provides those in the process of designing MRI rooms world-class expertise that is essential to making the entire design a success.

It is well known that MRI suites must address significant and growing, potentially adverse situations. Our proprietary “smart design” approach starts with conscientious and thorough prospective site planning to improve safety and create an environment that benefits patients, healthcare workers, and visitors.

Whether you are building a new MRI suite or renovating your existing MRI room, don’t award your contract until you talk to us. We’ll be able to help make your projects and clients successful.

PROJECT MANAGEMENT

We Approach Service Differently

We know how important in-the-field experience is to the success of the project. That’s why our Project Managers are former installation technicians who know what it takes to ensure smooth installations and make sure projects achieve the desired result.

Communication is key. Seamless, documented communication with all team members is the most important ingredient to a successful installation.

Our PMs know what the team (imaging directors, architects and construction contractors) needs for a successful design, timely installation and a shield that meets and complies with everyone’s expectations.

Our team takes his/her responsibility very seriously. Reconfirming design parameters that initiate and complete the shop submittal process, conveying these accurate parameters to IMEDCO’s design resources, explaining to other sub-contractors how to interpret the shops and keeping the customer’s project manager, the superintendent, the architect, and magnet vendor’s project manager/company representative current on all project matters is the primary responsibility.

The project manager is also responsible for coordinating all change order requests and diligently following the CO request until it is approved or rejected.

We consider Project Managers one of the most critical components of a successful MRI installation or MRI upgrade. You should expect the same. Just ask our clients. They will tell you the difference our project managers made in making sure expectations are met.

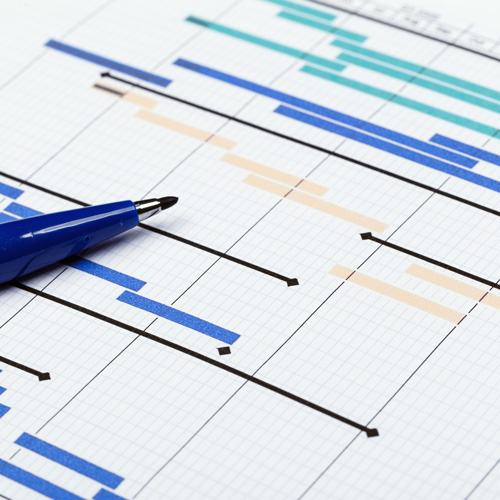

SCHEDULING

Schedule is critical for all resource planning and IMEDCO America recognizes that delays will cause issues for everyone involved. Site conditions that are not in accordance with approved shop drawings/submittals are costly and therefore IMEDCO includes a site inspection prior to the shipment of materials and installation resources. This inspection includes a complete check of all pertinent site conditions and identifies those areas (floor flatness survey, dimensional check of framed opening, etc.) that may not be compliant to the approved submittals. These discrepancies are identified to the GC so they can be addressed and corrected prior to the start of the installation phase to avoid unwanted and “billable” delays.

Schedule is critical for all resource planning and IMEDCO America recognizes that delays will cause issues for everyone involved. Site conditions that are not in accordance with approved shop drawings/submittals are costly and therefore IMEDCO includes a site inspection prior to the shipment of materials and installation resources. This inspection includes a complete check of all pertinent site conditions and identifies those areas (floor flatness survey, dimensional check of framed opening, etc.) that may not be compliant to the approved submittals. These discrepancies are identified to the GC so they can be addressed and corrected prior to the start of the installation phase to avoid unwanted and “billable” delays.

Once the construction schedule approaches the shield delivery date, the logistics to arrange material delivery and the mobilization of the installation resources begin. It is in the project’s interest to choose a reasonable date, as far in advance as possible, and then stick to it. Slipping the start date of Phase 1 could have an impact on the availability of necessary IMEDCO technician resources and may result in delays to the entire project.

INSTALLATION

Once the design is reviewed and approved by the team members (architect, user, contractor and magnet vendor) and fabricated in the IMEDCO America factory resources, the next step is to coordinate the shipment to the site and begin the installation phase.

The IMEDCO installation team always includes a senior factory-trained technician who accepts the role of the company representative for this phase of the project and handles the on-site communication and coordination with others. Whether he manages a fellow IMEDCO technician or local union resources, he is responsible for completing the install by following a controlled, methodical protocol that assures the shield package will perform as designed.

The IMEDCO installation team always includes a senior factory-trained technician who accepts the role of the company representative for this phase of the project and handles the on-site communication and coordination with others. Whether he manages a fellow IMEDCO technician or local union resources, he is responsible for completing the install by following a controlled, methodical protocol that assures the shield package will perform as designed.

He is responsible for the safety of himself, his fellow installers and others. He is OSHA-certified (40 hours); equipment handling certified and has first aid training. He has a basic understanding of physics and knows why a shield will or will not function as planned. He is capable of dealing with the challenges of handling magnetic shielding materials.

He is also certified in the use of testing equipment and will perform the two RF tests per the requirements of the contract and the magnet vendor test procedures.

Providing the site and customer with professional service and support is our trademark. You can expect it and you will get it. No exceptions.

MANUFACTURING

The IMEDCO America operations facility in Noblesville, IN is equipped to design, procure and fabricate the critical shielding components and materials needed for your MRI project. We maintain adequate inventory and stock levels to build and service your shielding needs in a timely fashion.

The IMEDCO America operations facility in Noblesville, IN is equipped to design, procure and fabricate the critical shielding components and materials needed for your MRI project. We maintain adequate inventory and stock levels to build and service your shielding needs in a timely fashion.

You can expect the product design will be followed and that quality and workmanship will be provided. This is a result of the legacy passed down from a demanding Swiss parent.

This facility and its’ resources have the capacity to serve the shielding needs of the USA and Canada.

SUBMITTAL & APPROVAL

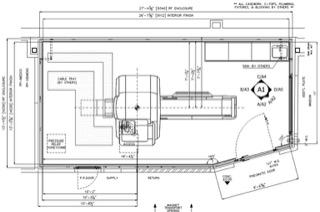

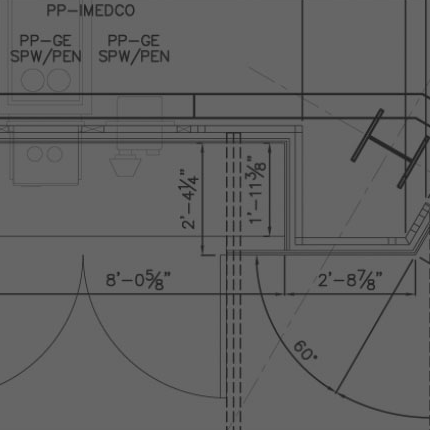

Another area where the IMEDCO America experience has proved valuable is in our Shop Drawings. If the architect and the General Contractor do not understand the shield design and what conditions are required, it makes for a difficult submittal and approval process. It also could lead to wrong interpretations of what is required and provided with the shield package.

Another area where the IMEDCO America experience has proved valuable is in our Shop Drawings. If the architect and the General Contractor do not understand the shield design and what conditions are required, it makes for a difficult submittal and approval process. It also could lead to wrong interpretations of what is required and provided with the shield package.

IMEDCO Shop Drawings detail all the specifics of the shield design. From minimum siting requirements, to existing structural conditions and references, to shield dimensions and equipment locations, mechanical, electrical and plumbing (MEP) service locations, shield component cut-sheets and interfaces and key magnet vendor details and accessories. IMEDCO submittals show it all. We insist on clear, documented communications throughout our contract and our shop drawings are no exception.

OTHER IMEDCO SERVICES

Baseline Testing | RF Troubleshooting | RF Shield Repairs | Door Servicing | Shield Modifications For MRI Upgrades | Value Engineering | Door Upgrade/Replacement | Magnetic Shielding Modeling | LED Lighting Packages